Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

Toys Testing Equipment

Toys Testing Equipment Physical & Mechanical Testing

Physical & Mechanical Testing Flammability Testing

Flammability Testing Clamps for Toys Testing

Clamps for Toys Testing Electronic Toy Testing Equipment

Electronic Toy Testing Equipment ISO8124-4,EN71-8

ISO8124-4,EN71-8 Footwear Testing Equipment

Footwear Testing Equipment Fatigue Testing Equipment

Fatigue Testing Equipment Flexing Test Equipment

Flexing Test Equipment Impact Testing Equipment

Impact Testing Equipment Abrasion Testing Equipment

Abrasion Testing Equipment Waterproofness Tester

Waterproofness Tester Friction & Slip Testing

Friction & Slip Testing Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Mattress Testing Machine

Mattress Testing Machine Table Testing Machine

Table Testing Machine Chair Testing Machine

Chair Testing Machine Textile Testing Equipment

Textile Testing Equipment Fabric and Garment Testing Instruments

Fabric and Garment Testing Instruments Color Fastness Testing Equipment

Color Fastness Testing Equipment

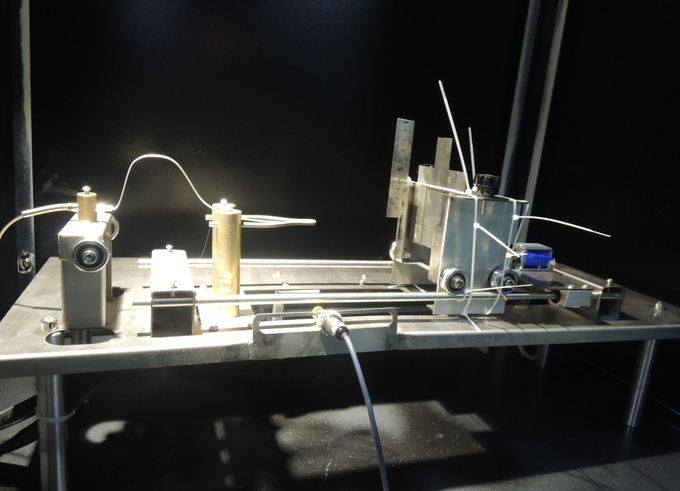

IEC 60695 UL746 Glow Wire Test Apparatus

Electronic Testing Equipment Glow Wire Tester

Product description

This instrument is designed and manufactured according to the requirements of "Glowing Wire Test Method" in IEC60695, GB5169.10-11 and GB4706.1. It is suitable for electrical and electronic products, household appliances and their materials for ignition hazard test, simulating hot components or overload resistors. Thermal stress caused by a heat source or ignition source in a short time. The instrument adopts galvanized sheet cold-rolling electrostatic spraying and adopts full-color seven-inch touch operation display. The test is easy and efficient, easy to operate and stable in performance. It is suitable for fire resistance test at all levels of quality inspection departments and related enterprises.

Product Features

1. Adopt single-chip microcomputer + touch screen control, high-precision temperature meter independent electronic control system to solve the problem that the actual conversion accuracy of digital system of PLC system can not be achieved, and improve the anti-interference ability. Microcomputer control is more precise.

2. Start, timing, exhaust, lighting, and heating are all implemented on the touch screen; after a group of tests, the device automatically jumps out and saves, just edit the saved name; all saved data can be queried in historical data.

3. Seven inch color touch screen

4. Intelligent 7mm limit adjustment

5. Fixture adapts to various shape and size samples

6. Free movement in X and Z directions for convenient sample positioning

7. With one-button operation, one button completes the whole test process during the test, without switching between complicated buttons

8. The sample car adopts a fully enclosed structure and will not roll over.

9. Equipped with flame height gauge for easy viewing of flame height

Main Technical Parameters

1. The red line photoelectric stop switch is used to make the limit more precise.

2. The thyristor controls the temperature regulation system to make the temperature adjustment more accurate.

3. Time and temperature digital display, convenient observation and record

4. Test background: black background, background illumination ≤ 20 Lux.

5. Test process: automatic control of test procedures, independent ventilation

6. Combustion test area volume: > 0.5 cubic, length * width * height about 900mm × 590mm × 1050mm, (can be customized according to customer requirements stainless steel chassis, 0.75 cubic or 1 cubic)

7. Dimensions: width 1160mm × depth 600mm × height 1310 (including feet) mm

|

Glow wire temperature |

500~1000°C±2°C continuously adjustable |

|

Hot time |

0-999.9s ± 0.1s adjustable (usually 30s) |

|

Light-off time |

0-999.9s ± 0.1s, automatic recording, manual suspension |

|

Extinguished time |

0-999.9s±0.1s, automatic recording, manual pause |

|

Thermocouple |

Φ0.5mm imported armored (K type) thermocouple |

|

Hot wire |

Φ4 mm nickel-chromium wire |

|

Hot penetration depth |

7mm ± 0.5mm |

|

Sample pressure |

1N ± 0.2N |

|

Test speed |

14mm/s |

|

Working power supply |

AC220V, 50Hz, ≤500W |

How do you test a glow wire?

Glow wire testing is performed by heating an element to a pre-determined temperature. The heated element is referred to as the glow wire. The sample to be tested is fixture in place and tissue paper is positioned directly below the sample.

Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

English

English 中文

中文 Español

Español française

française العربية

العربية Русский

Русский