Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

Toys Testing Equipment

Toys Testing Equipment Physical & Mechanical Testing

Physical & Mechanical Testing Flammability Testing

Flammability Testing Clamps for Toys Testing

Clamps for Toys Testing Electronic Toy Testing Equipment

Electronic Toy Testing Equipment ISO8124-4,EN71-8

ISO8124-4,EN71-8 Footwear Testing Equipment

Footwear Testing Equipment Fatigue Testing Equipment

Fatigue Testing Equipment Flexing Test Equipment

Flexing Test Equipment Impact Testing Equipment

Impact Testing Equipment Abrasion Testing Equipment

Abrasion Testing Equipment Waterproofness Tester

Waterproofness Tester Friction & Slip Testing

Friction & Slip Testing Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Mattress Testing Machine

Mattress Testing Machine Table Testing Machine

Table Testing Machine Chair Testing Machine

Chair Testing Machine Textile Testing Equipment

Textile Testing Equipment Fabric and Garment Testing Instruments

Fabric and Garment Testing Instruments Color Fastness Testing Equipment

Color Fastness Testing Equipment

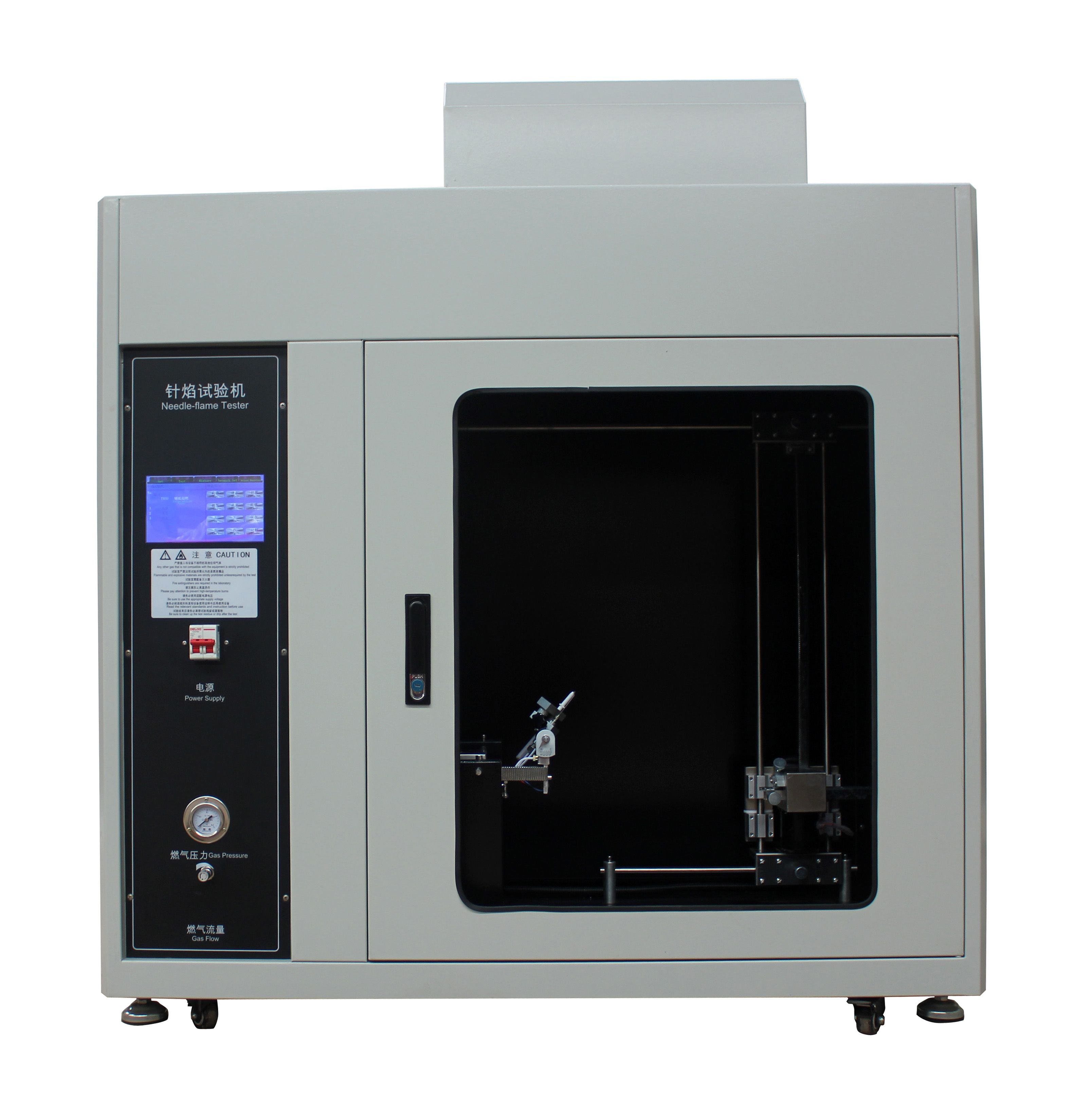

IEC 60695 Needle Flame Test Apparatus for Electronic Components

Electronic Product Needle Flame Test Apparatus , IEC 60695 Needle Flame Test Chamber

Introductions

Needle Flame Test Chamber is used to test the resistance of fire caused by an interior fault such as leakage current in cable & wire and the like. It meets the requirements of Chinese GB4706.1, GB5169.5, and IEC60695-2-2 and IEC61347-1 standards.

Application

Electrical & electronic product

Components and accessories of household appliances

Features

a. All stainless steel and brass constructions.

b. Burner can be ignited automatically.

c. Temperature and test time display by digital meters.

d. A big window in the door makes your viewing more convenient.

Technical parameters

|

Needle burner |

inner hole diameter Φ 0.5mm ± 0.1mm, Diameter,≤Φ 0.9mm, length ≥ 35mm, stainless steel |

| Burner angle |

0~45° (adjust flame height) |

|

Thermocouple |

Ø0.5mm Type K (Ni/Cr - Ni/Al), armored sheath can withstand temperature-40°C~ 1100°C |

|

Burning time |

0-999.9 s ± 0.1 s adjustable (usually selected for 30s) |

|

Burning time |

12mm ± 1mm (with height measurement instruments) |

|

Flame Height |

butane gas/Butane gas, min. 95% purity (can use bottled lighter gases) |

|

Temperature Test Range |

0~1000°C |

|

Flame Temperature Requirements |

from 100 °C ± 2 °C liters to 700 °C ± 3 °C time in 23.5 seconds ± 1 seconds |

|

Standard Copper Block |

4mm±0.01mm, weight.0.58g±0.01g before drilling. Cu-ETP |

|

Test process |

automatic control, independent convulsions |

|

Chamber |

≥0.5m3 |

|

Control |

Using single chip microcomputer + touch screen control |

|

Consult standard |

GB/T5169.10-2006 , IEC60695-11-5:2000,UL746A |

|

Power Supply |

800VA ,220V, 48-60Hz |

|

Display panel language |

English(customize available) |

The needle-flame test is used for the assessment of fire hazard caused by small flames, which may result by ignition of a failing component of electric equipment. Summary of test method: The test specimen is arranged in a vertical position. ... The specimen is subjected to a 12 mm flame (Propane, at least 95% pure).

Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

English

English 中文

中文 Español

Español française

française العربية

العربية Русский

Русский