Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

Toys Testing Equipment

Toys Testing Equipment Physical & Mechanical Testing

Physical & Mechanical Testing Flammability Testing

Flammability Testing Clamps for Toys Testing

Clamps for Toys Testing Electronic Toy Testing Equipment

Electronic Toy Testing Equipment ISO8124-4,EN71-8

ISO8124-4,EN71-8 Footwear Testing Equipment

Footwear Testing Equipment Fatigue Testing Equipment

Fatigue Testing Equipment Flexing Test Equipment

Flexing Test Equipment Impact Testing Equipment

Impact Testing Equipment Abrasion Testing Equipment

Abrasion Testing Equipment Waterproofness Tester

Waterproofness Tester Friction & Slip Testing

Friction & Slip Testing Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Mattress Testing Machine

Mattress Testing Machine Table Testing Machine

Table Testing Machine Chair Testing Machine

Chair Testing Machine Textile Testing Equipment

Textile Testing Equipment Fabric and Garment Testing Instruments

Fabric and Garment Testing Instruments Color Fastness Testing Equipment

Color Fastness Testing Equipment

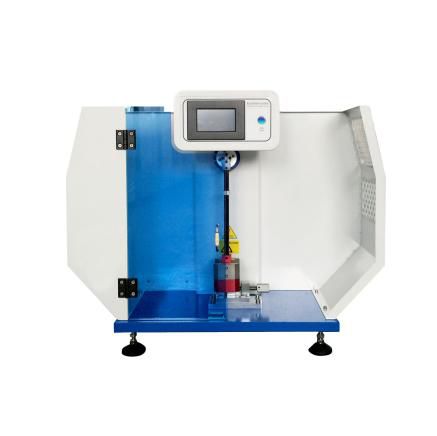

Cantilever Beam Impact Testing Machine

Cantilever Beam Impact Testing Machine

Product introduction

The cantilever beam impact tester is used to determine the impact toughness of non-metallic materials such as plastics, reinforced nylon, fiberglass, ceramics, cast stone, plastic electrical appliances, and insulating materials. The pendulum impact testing machine is a common equipment for quality inspection by scientific research units, universities and non-metallic materials manufacturers. The machine is a simple structure, convenient operation and high precision test. The digital impact test machine adopts high precision. The encoder technology has the characteristics of high precision, good stability and large measuring range. The digital measurement shows the impact strength and average value, the energy loss is automatically corrected, and the test report is printed.

The implementation of standards

ISO 180-2000 "Determination of impact strength of plastic-hard material cantilever beam"

JB/T8761—1998 “Plastic Cantilever Beam Impact Tester”

ASTM D256-2010 "Test Method for Determining Impact Strength of Plastic IZOD Pendulum"

Product features

1. High-precision intelligent controller with LCD display for intuitive and accurate data reading

2. Domestic use of carbon fiber pendulum rod, in the impact direction, improve the rigidity of the material, and focus the impact mass on the centroid of the pendulum, truly vibration-free impact test, and the service life increases.

3. Imported high-resolution digital encoder, the angle test accuracy is higher and more stable

4. Aerodynamic principle of hammer and imported ball bearings, greatly reducing the friction loss caused by machinery

5. Automatic calculation of the final result, the test data can save 12 sets of data and average

6.IZOD impact tester can choose Chinese and English operation interface, test results can choose J/m, KJ/m2, kg-cm/cm, ft-ib/in and other units

7. Built-in micro printer print test data

Technical parameters

| Display mode | color touch screen (Chinese and English) |

| Angle sensor brand and accuracy | original imported Omron encoder, accuracy to 0.01 ° |

| Energy display accuracy | 0.01J |

| Impact speed | 3.5m / s |

| Pendulum energy | (5.5D) 2.75J, 5.5J |

| Pendulum angle | 150° |

| Pendulum center to impact blade distance | 335mm |

| Impact blade to the upper plane distance of the jaw | 22mm |

| Boring edge fillet radius | R=0.8±0.2mm |

| Machine weight | 85kg |

| Power supply voltage | AC220V±10% 50HZ |

Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

English

English 中文

中文 Español

Español française

française العربية

العربية Русский

Русский