Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

Toys Testing Equipment

Toys Testing Equipment Physical & Mechanical Testing

Physical & Mechanical Testing Flammability Testing

Flammability Testing Clamps for Toys Testing

Clamps for Toys Testing Electronic Toy Testing Equipment

Electronic Toy Testing Equipment ISO8124-4,EN71-8

ISO8124-4,EN71-8 Footwear Testing Equipment

Footwear Testing Equipment Fatigue Testing Equipment

Fatigue Testing Equipment Flexing Test Equipment

Flexing Test Equipment Impact Testing Equipment

Impact Testing Equipment Abrasion Testing Equipment

Abrasion Testing Equipment Waterproofness Tester

Waterproofness Tester Friction & Slip Testing

Friction & Slip Testing Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Mattress Testing Machine

Mattress Testing Machine Table Testing Machine

Table Testing Machine Chair Testing Machine

Chair Testing Machine Textile Testing Equipment

Textile Testing Equipment Fabric and Garment Testing Instruments

Fabric and Garment Testing Instruments Color Fastness Testing Equipment

Color Fastness Testing Equipment

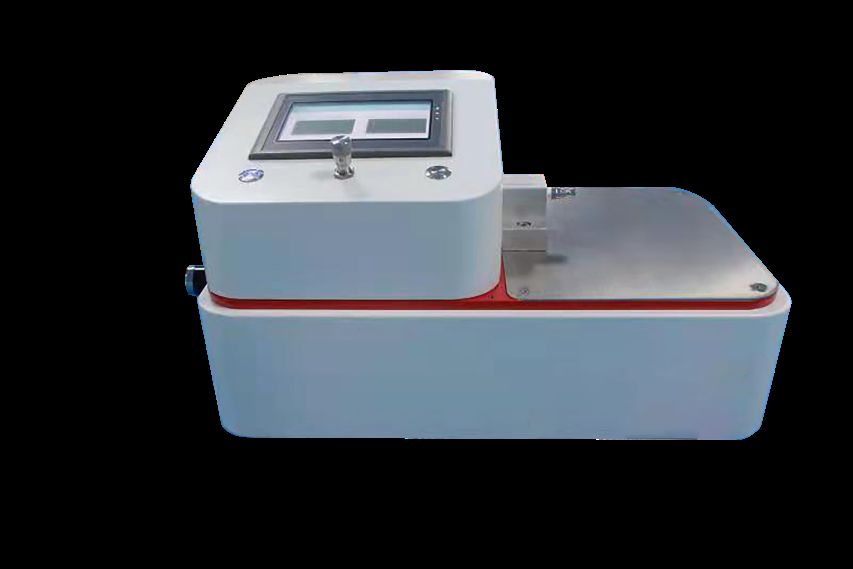

Cap Of Pen Air Circulation Tester

Stationery Tester Cap Of Pen Air Circulation Tester

Cap Of Pen Air Circulation Tester Application

Pen cap air flow tester is used to stationery manufacturers pen cap ventilation qualified rate inspection, quality supervision departments of stationery manufacturers to produce pen cap inspection, third-party inspection agencies, etc.

Standards

① BS7272-1/-2: 2008 Safety standard for choking prevention of pen caps and pens plugs

② JTS S 6060:1996 Safety requirements for writing pens and marker pens caps for children up to and including 14 years of age

③ ISO 11540:1993 Safety requirements for writing pens and marker caps for children up to and including 14 years of age

④ GB 21027:2007 General requirements for the safety of student products

⑤ GB/T 24110-2009 Safety requirements and test methods for pen caps and end caps for import and export pen products

Principle

This machine is based on the "GB21027-2020 general requirements for the safety of student products" standard (that is, under a pressure of 1.33KPa, the air ventilation capacity of the pen cap must reach 8L/min) production, is a special testing instrument customized for pen cap ventilation testing. Mainly the pen cap is completely inserted into a suitable diameter, air flow, pressure difference between the two ends of the elastic tube, in order to measure the air flow of the pen cap.

Technical parameters

1.Flow control valve: ±0.1L/min/resolution 0.001L/min

2. Flow meter: can measure air flow at 5L/min and 10L/min, at least accurate to ±0.2 L/min

3. Manometer: able to measure at least 4Kpa of pressure.

4. Manometer accuracy: ±0.1kpa

5. Elastic tube: can be equipped with 7~14mm hose, can measure 6~16mm specification pen cap

6. Control mode: LCC touch screen control

7. Pen cap test components: self-locking quick interface, connect the pen cap convenient and fast.

8. Gas source device requirements: in the pressure range of 4kPa ~ 50kPa, stable flow is at least 25L/min

Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

English

English 中文

中文 Español

Español française

française العربية

العربية Русский

Русский