Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

Toys Testing Equipment

Toys Testing Equipment Physical & Mechanical Testing

Physical & Mechanical Testing Flammability Testing

Flammability Testing Clamps for Toys Testing

Clamps for Toys Testing Electronic Toy Testing Equipment

Electronic Toy Testing Equipment ISO8124-4,EN71-8

ISO8124-4,EN71-8 Footwear Testing Equipment

Footwear Testing Equipment Fatigue Testing Equipment

Fatigue Testing Equipment Flexing Test Equipment

Flexing Test Equipment Impact Testing Equipment

Impact Testing Equipment Abrasion Testing Equipment

Abrasion Testing Equipment Waterproofness Tester

Waterproofness Tester Friction & Slip Testing

Friction & Slip Testing Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Mattress Testing Machine

Mattress Testing Machine Table Testing Machine

Table Testing Machine Chair Testing Machine

Chair Testing Machine Textile Testing Equipment

Textile Testing Equipment Fabric and Garment Testing Instruments

Fabric and Garment Testing Instruments Color Fastness Testing Equipment

Color Fastness Testing Equipment

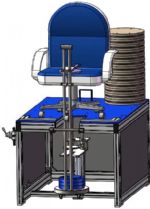

SL-T33 Furniture Universal Test Machine

Furniture Universal Tester/ EN 1728/EN12520 chair test machine/ multifunctional testing machine/

Product Introduction

This machine is used for static load test and durability test of table, desk and other furniture. Each pneumatic device can work together or independently, and can also be adjusted to meet different test requirements

Test Standards

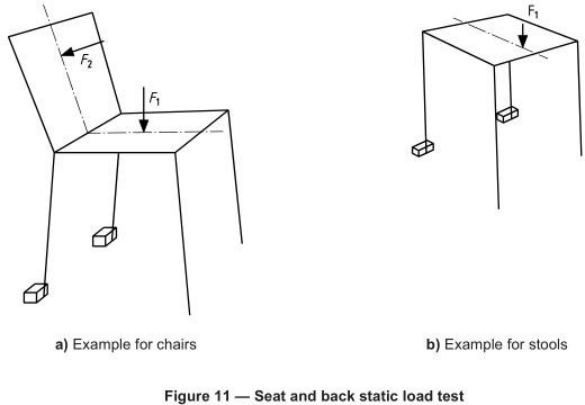

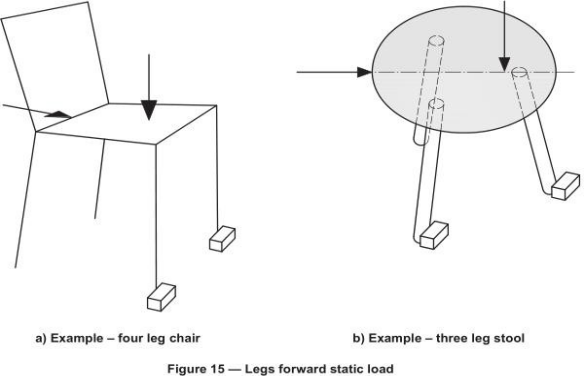

EN 1728, EN 12520

Technical Parameters

| Basic Test Frame | 3x3x2m,be made of 80x80mm Alu.material |

| Load air cylinder | Seating load: 200kg; Back load:100kg; Arm:100kg; Leg:100kg |

| Force sensor | High precision brand sensors 7 sets |

| Control method | PLC and LCD touch screen |

| Counter | 0~999999 (adjustable) |

| Force adjust |

Precision pressure valve equipment with sensor to display |

| Air supply | 7kgf/cm^2 |

| Power supply | 1∮ AC 220V 50Hz 5A |

STANDARD ACCESSORIES:

| Capacity | 200kg (Imported Sensor) |

| Controller and Interface | Programmable logic controller + touch screen interface |

|

Accessories |

Chair Armrest Fixture x 4 pieces 2 for durability test; 2 for strength test |

|

Seat loading pad x 1 piece for chair seat static load & durability tests |

|

|

Smaller seat loading pad x2 pieces for Chair Front edge static load & durability tests |

|

|

Back loading pad x 1 piece for chair back static load & durability tests |

|

|

Leg loading pad x 1 pieces for horizontal cylinder for balance load |

|

|

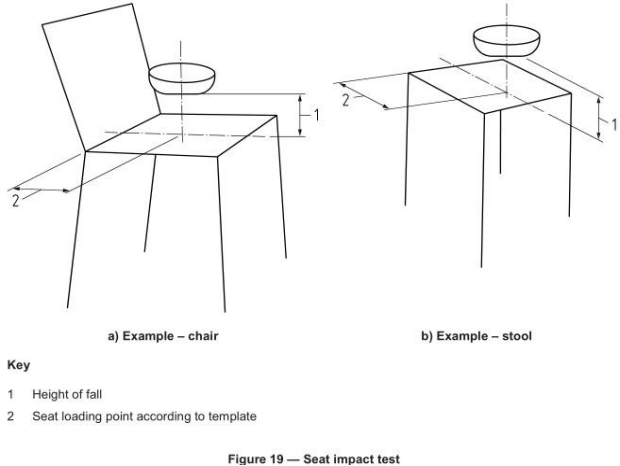

Impactor x 1 piece for chair seat impact test |

|

|

standard foam x 1 piece for chair seat impact test |

|

|

Impact hammer x 1 piece for chair back & arm impact test; |

|

| Air Pressure | 7 bar |

|

1. All load, cycle rate, speed can be adjusted by the controller. 2. The test results can be output by Word. 3. The actuator is easy adjust to perform Vertical and horizontal static test. |

|

Features:

1. Aluminum alloy profile frame structure. All loading components can be moved and fixed along the frame aluminum profile for optimal loading position.

2. All the cylinder parts of the loading force adopt the shaft core hexagonal non-rotating cylinder to keep the loading pad from rotating loading.

3. The vertical cylinder assembly is mounted on a "base" that slides freely horizontally and automatically shifts and stays vertical when subjected to lateral forces.

4. Easy operation, a person can quickly complete the sample clamping, without any tool assistance.

All channels can be set in independent or combined action mode, and all channels are set with independent touch switches.

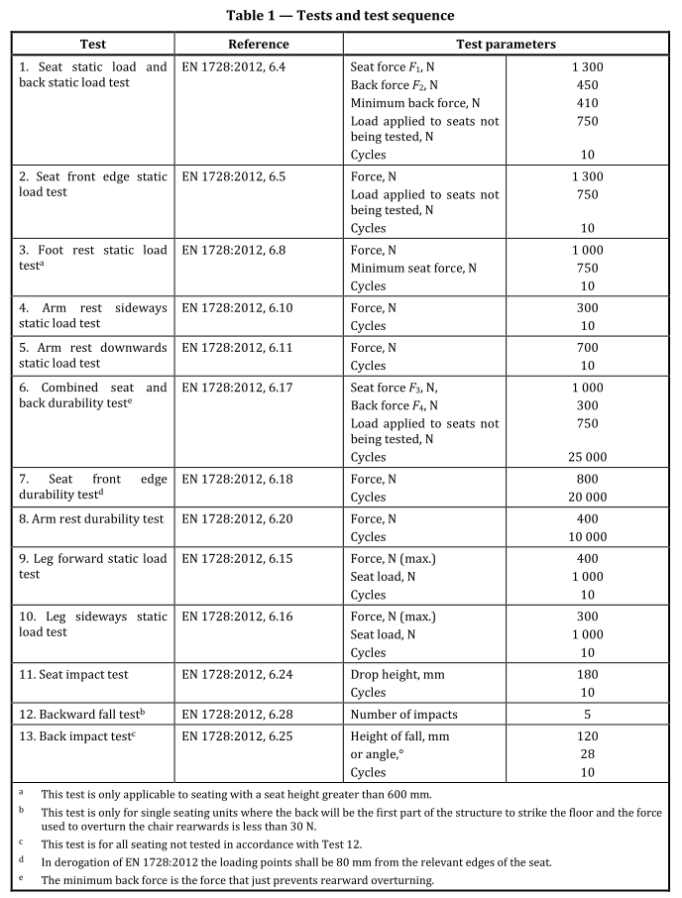

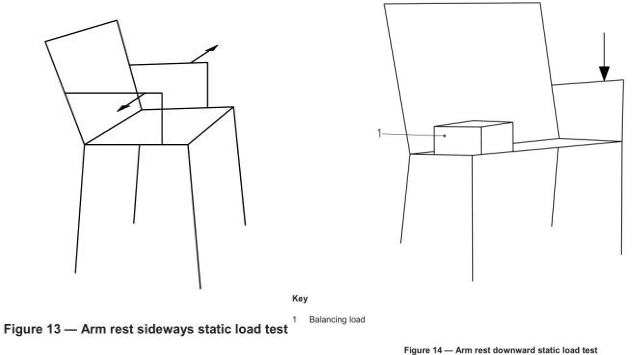

TEST ITEMS FOR CHAIR SEAT,BACK,ARM WITH STRENGTH AND DURABILITY SETS REFERS TO EN BS EN 1728 & EN12520

| NO. | Name | Pictures |

| 1 | Seat surface loading block |

|

| 2 | Seat back loading pad (square) |

|

| 3 | Small seat surface loading pad (200MM) |

|

| 4 | Universal loading pad |

|

| 5 | Armrest test fixture |

|

| 6 | Block for Height |

|

| 7 | Impact block |

|

| 8 | Impact Hammer |

|

| 9 | 350x350x25mm Test Foam |

|

| 10 |

CMD Loading point template |

|

TEST IMAGE FOR ARM STRENGTH & DURABILITY TESTS

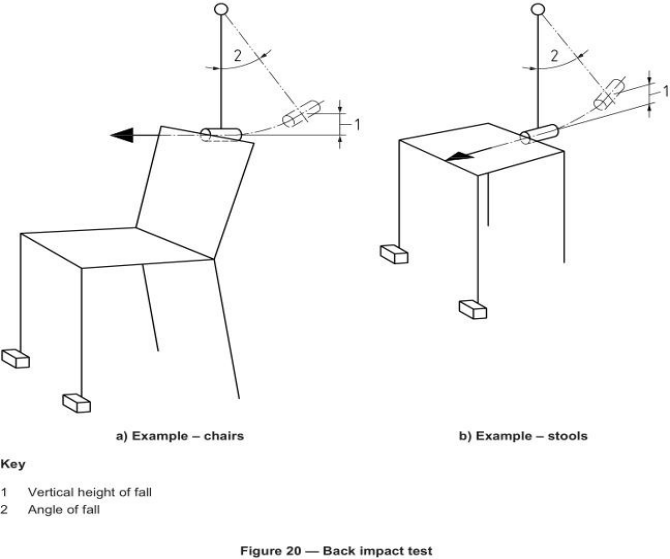

TEST IMAGE FOR ARM & BACK IMPACT TESTS

TEST IMAGE FOR SEAT IMPACT TEST

Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

English

English 中文

中文 Español

Español française

française العربية

العربية Русский

Русский