Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

Toys Testing Equipment

Toys Testing Equipment Physical & Mechanical Testing

Physical & Mechanical Testing Flammability Testing

Flammability Testing Clamps for Toys Testing

Clamps for Toys Testing Electronic Toy Testing Equipment

Electronic Toy Testing Equipment ISO8124-4,EN71-8

ISO8124-4,EN71-8 Footwear Testing Equipment

Footwear Testing Equipment Fatigue Testing Equipment

Fatigue Testing Equipment Flexing Test Equipment

Flexing Test Equipment Impact Testing Equipment

Impact Testing Equipment Abrasion Testing Equipment

Abrasion Testing Equipment Waterproofness Tester

Waterproofness Tester Friction & Slip Testing

Friction & Slip Testing Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Mattress Testing Machine

Mattress Testing Machine Table Testing Machine

Table Testing Machine Chair Testing Machine

Chair Testing Machine Textile Testing Equipment

Textile Testing Equipment Fabric and Garment Testing Instruments

Fabric and Garment Testing Instruments Color Fastness Testing Equipment

Color Fastness Testing Equipment

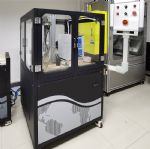

ISO 9185 Molten Metal Splash Test Apparatus

Product Profile

The thermal penetration resistance of protective clothing materials used to prevent a large number of molten metal splashes was evaluated by the anti-liquid molten metal splashing test device developed according to ISO9185 standard. Medium such as molten aluminium, molten cryolite, molten copper, molten iron and spatter of molten low carbon steel directly acted on the surface of the material. The penetration resistance of protective clothing materials was evaluated by the damage degree of PVC film attached to the back of the sample.

Performance characteristics

1. The anti-liquid metal bead splash test device includes high frequency heating device, sample frame, crucible support, sample frame rotating device, high temperature radiometer, etc.

2. The high temperature radiometer can measure the melting metal temperature up to 1650 C, and the accuracy can reach (+10) C.

3. The metal solution pouring device rotates at a constant angular speed and can pour the sample.

4. High frequency heating device, which can be used to melt aluminium, copper, iron and mild steel, can be heated to 1800 degrees.

5. Protective framework and toughened glass observation window are equipped to protect the safety of testers.

6. The bracket arm control unit can be used for lifting and rotating the crucible bracket.

Standard

ISO 9185:2007

Size: 1000mm (L) * 1000mm (W) * 1500mm (H)

Weight: 180KG

Installation requirements: Electricity requirements: 220V, 10A; 380V, 60A

Ambient temperature: 10 ℃ to 35 ℃

Gas requirements: air compressor air source, external diameter 8mm

Water source requirement: tap water source, external diameter 15 mm

How are fire protection products tested?

Many fire tests are run by official laboratories for the purpose of product certification. However, some manufacturers of fire protection products also maintain their own facilities and run tests for R & D purposes before going to the expense and exposure of a test at a third party facility.

Anti-Liquid Molten Metal Splash Test Device.pdf

Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

English

English 中文

中文 Español

Español française

française العربية

العربية Русский

Русский