Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

Toys Testing Equipment

Toys Testing Equipment Physical & Mechanical Testing

Physical & Mechanical Testing Flammability Testing

Flammability Testing Clamps for Toys Testing

Clamps for Toys Testing Electronic Toy Testing Equipment

Electronic Toy Testing Equipment ISO8124-4,EN71-8

ISO8124-4,EN71-8 Footwear Testing Equipment

Footwear Testing Equipment Fatigue Testing Equipment

Fatigue Testing Equipment Flexing Test Equipment

Flexing Test Equipment Impact Testing Equipment

Impact Testing Equipment Abrasion Testing Equipment

Abrasion Testing Equipment Waterproofness Tester

Waterproofness Tester Friction & Slip Testing

Friction & Slip Testing Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Mattress Testing Machine

Mattress Testing Machine Table Testing Machine

Table Testing Machine Chair Testing Machine

Chair Testing Machine Textile Testing Equipment

Textile Testing Equipment Fabric and Garment Testing Instruments

Fabric and Garment Testing Instruments Color Fastness Testing Equipment

Color Fastness Testing Equipment

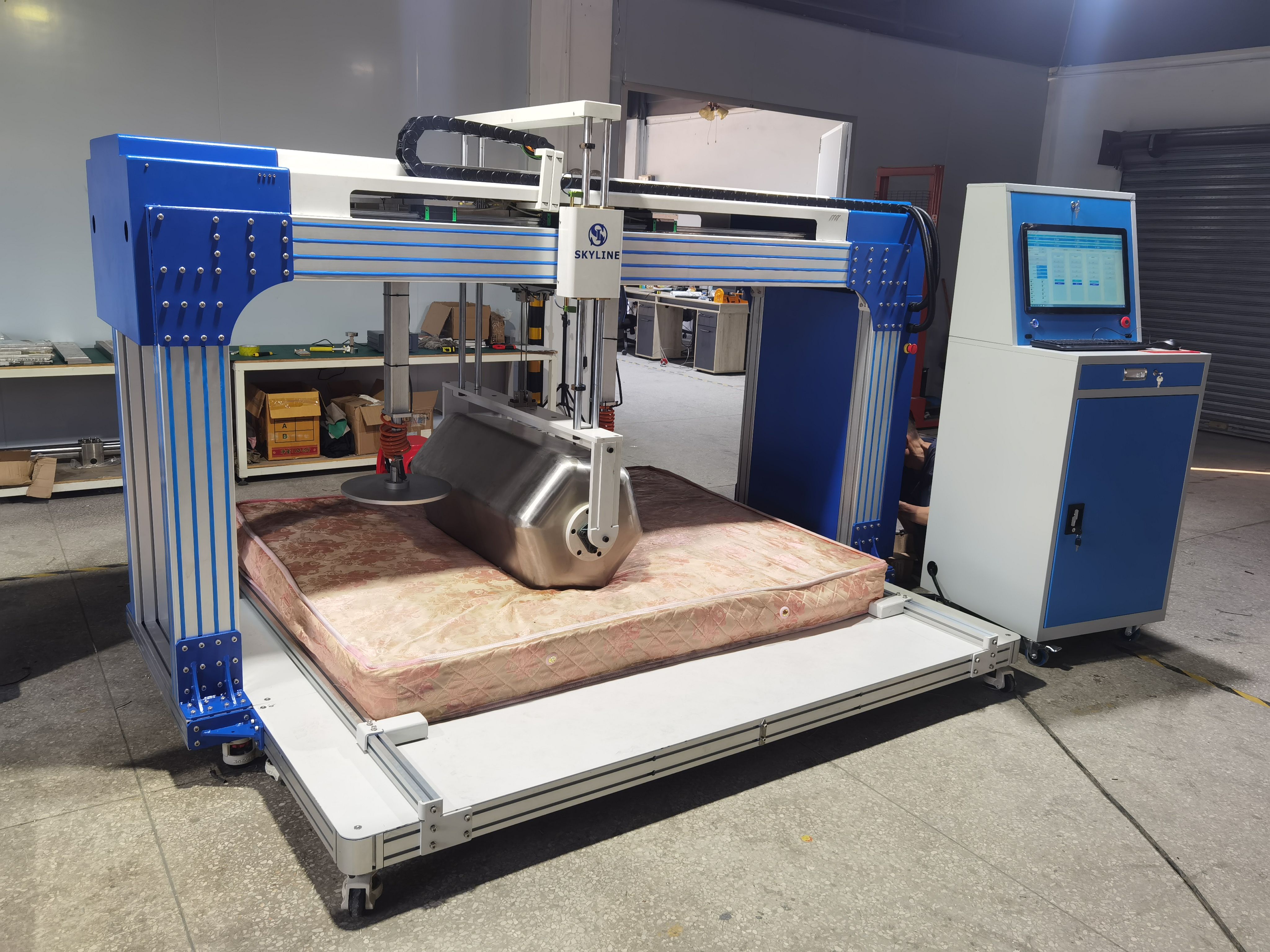

Mattress Rolling Durability & Hardness Testing Machine

SL-T07I Mattress Rolling Durability & Hardness Testing Machine

Product Introduction

To determine the durability and hardness of any type of mattress and boxspring unit (regardless of the materials) by simulating long term use condition.

The mattress durability tester is used for Boxspring Mattresses, Innerspring Mattresses, Polyurethane Mattresses

Test Standards

EN1957, ASTM F1566, QB/T1952-2, GB/T26706

|

Capacity |

2kN Sensor*1 |

|

|

Servo motor |

0.4kW*2、1.5kW*1 |

|

|

Cylinder stroke |

Stroke 500mm, Max thrust 1.39kN |

|

|

Control mode |

PLC and LCD touch screen |

|

|

Test Speed |

10~20 times/min(GB/EN 16±2 times/min,ASTM 20 times/min MAX) |

|

|

Rolling stroke |

GB/EN Rolling 250mm left and right from the center |

Total rolling distance from the center if 70% of the mattress , and the max is 965mm |

|

Rolling drive |

Servo motor with synchronous belt drive |

|

|

Accuracy of detector |

Displacement accuracy:±0.1mm; Loading accuracy ±0.1N(0.1-480N) |

|

|

Roller |

GB/EN Round Cylinder:140kg, Length 1000mm,Diameter 300mm, R20mm |

ASTM Hexagonal barrel: 109kg, Length 36±3in(915±75mm) |

|

Rolling fatigue test |

GB/EN Round Cylinder: 30000 cycles |

ASTM Hexagonal barrel:100000 cycles |

|

Bed edge durability test |

Capacity 1000N, test cycles 5000 |

|

|

Max. mattress size |

2200x2000x400mm(L*W*H) |

|

|

Power Supply |

1∮ AC 220V 50Hz |

|

|

Air Source |

≥6kg/cm² |

|

|

Main Test Items |

Rolling Fatigue Test, Hardness Test, Height Loss Test |

|

Technical Parameters

Durability Test

|

Roller |

GB/EN Round Cylinder:140kg, Length 1000mm,Diameter 300mm, R20mm |

ASTM Hexagonal barrel: 109kg, Length 36±3in(915±75mm) |

|

Rolling fatigue test |

GB/EN Round Cylinder: 30000 cycles |

ASTM Hexagonal barrel:100000 cycles |

|

Maximum size of mattress |

2.2m×2.5m |

|

|

Test speed |

0-20r/min |

|

|

Control method |

PLC+ touch screen |

|

|

Dimension |

3000mm×1510mm×2010mm |

|

|

Power |

AC220V±10%, 50/60Hz, single phase |

|

|

Accessory |

One Hexagonal barrel, Cylinder weight |

|

|

According to different mattress to adjust the rolling stroke (adjust the limit switch position) |

||

|

Low coefficient of friction guide, ensure full drum weight on the mattress. |

||

|

LCD Touch Screen display provides easy control and setting |

||

Height Loss and Hardness Test

|

The loading platen |

(EN1957): 355 mm diameter, spherical curvature radius 800mm front edge curvature radius 20mm |

|

(ASTM F1566): 344 +/-5 mm diameter, 1mm radius bottom edge |

|

|

The loading speed |

20 ~ 300mm/min |

|

Test run |

500mm |

|

Capacity |

200kg |

Durability Test of bed edge (EN)

|

Test load capacity |

1000N |

|

Test Cycle |

5000 |

|

Driving Method |

Air Cylinder |

|

Hold time |

Maintain for (3+/-1)s |

Features

1. The whole machine frame made of high quality aluminum, with smart and elegant shape

2. Delta brand PLC and Servo Motors

3. Machine configuration two motors, one for the vertical direction of the roller, and the other is responsible for the horizontal direction of the drum drive, the two motors are used in DELTA servo motor

4. Machine configuration alarm device, indicating the safe operation

5. Electric lifts the Roller, easy to operate.

6. PLC controller with large colorful touch panel

7. Automatically stops after preset cycles completed

8. over moving limit protection

9. Wooden roller softly contacts the surface of the mattress

Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

English

English 中文

中文 Español

Español française

française العربية

العربية Русский

Русский

.png)