Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

Toys Testing Equipment

Toys Testing Equipment Physical & Mechanical Testing

Physical & Mechanical Testing Flammability Testing

Flammability Testing Clamps for Toys Testing

Clamps for Toys Testing Electronic Toy Testing Equipment

Electronic Toy Testing Equipment ISO8124-4,EN71-8

ISO8124-4,EN71-8 Footwear Testing Equipment

Footwear Testing Equipment Fatigue Testing Equipment

Fatigue Testing Equipment Flexing Test Equipment

Flexing Test Equipment Impact Testing Equipment

Impact Testing Equipment Abrasion Testing Equipment

Abrasion Testing Equipment Waterproofness Tester

Waterproofness Tester Friction & Slip Testing

Friction & Slip Testing Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Mattress Testing Machine

Mattress Testing Machine Table Testing Machine

Table Testing Machine Chair Testing Machine

Chair Testing Machine Textile Testing Equipment

Textile Testing Equipment Fabric and Garment Testing Instruments

Fabric and Garment Testing Instruments Color Fastness Testing Equipment

Color Fastness Testing Equipment

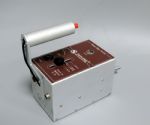

SL-S12 Sharp Edge Tester

EN71-1 Children Toys Testing Equipment Toy Safety Sharp Edge Tester

Sharp Edge Test Equipment Application

Sharp edge tester is used to determine whether the edge of a toy or item is a sharp edge with an unreasonable risk of injury.

Sharp Edge Testing Machine Product Information

Sharp edge tester is used to determine whether accessible edges on toys are likely to cause injury. A self-adhesive PTFE tape is attached to a mandrel, which is then rotated for a single 360-degree revolution along the accessible edge being tested. If the tape is cut in half or longer in length (approx. 13 mm), the edge is identified as a hazardous sharp edge. Toys intended for use by children under 8 years old are subject to this requirement before or after use & abuse testing.

Sharp Edge Test principle

The steel shaft used to simulate children's fingers needs to be hardened. The surface Rockwell hardness should be no less than 40, the surface roughness should not be greater than 0.40 microns, and the diameter should be 9.35 mm ± 0.12 mm. A layer of simulated artificial skin tape was applied perpendicularly to a steel shaft wrapped with simulated artificial skin glue with a force of 6 N (1.35 lb). The steel shaft was constant tangent at 23 mm/sec ± 4 mm/sec. The speed is rotated for one week. Check the edge of the test to cut (cut) the simulated artificial skin adhesive paper. If cut (cut), the tested edge is defined as a potentially dangerous sharp edge.

Technical parameters

| Dimension | (L*W*H)29*19*10cm |

| Weight | 3.5Kg |

| Speed | 1.00±0.08 In/s |

| Fixed force | 1.35LB |

| Material | stainless steel |

| Accessories | Tiefo Long Tape PTFE Tape |

| Standard | ASTM F963 4.7, EN 71-1 8.11, 16 CFR 1500.49, ISO 8124-1 5.8 |

Please review video of the Sharp Edge Tester operation as below link:

Note

1.Independent carton packaging

2.In Stock

Standards

1.Diameter of rotary mandrel shown in table 1:

| Standard | EN71-1 | ASTM F 963/16CFR1500.49 |

| Nominal value | φ(9.53±0.12)mm | φ(0.375±0.005)inch |

| Measured value | φ9.450mm | φ0.3720 inch |

2.Measured value of force shown in table 2:

| Standard | EN71-1 | ASTM F 963/16CFR1500.49 |

| Nominal value | (6±0.5)N | 1.35 lbf |

| Measured value | 6.00N | 1.35 lbf |

3.Rotate speed of rotary mandrel shown in table 3:

| Standard | EN71-1 | ASTM F 963/16CFR1500.49 |

| Nominal value | (23±4)mm/s | (1.00±0.08)inch/s |

| Measured value | 19.3mm/s | 0.760inch/s |

4.Roughness of rotary mandrel shown in table 4:

Standard

EN71-1

ASTM F 963/CFR150.49

Nominal value

≤0.4 μm

≤16 micro inch

Measured value

0.15 μm

5.9 micro inch

How do you test sharp edges?

The edge shall be identified as sharp if it completely cuts through the tape for a length of not less than 1/2 inch (13 millimeters) at any force up to 1.35 pounds (6.00 Newtons). (2) Procedure. (i) The edge of the sample to be tested shall be held in such a manner that it does not move during the test.

Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

English

English 中文

中文 Español

Español française

française العربية

العربية Русский

Русский