Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

Toys Testing Equipment

Toys Testing Equipment Physical & Mechanical Testing

Physical & Mechanical Testing Flammability Testing

Flammability Testing Clamps for Toys Testing

Clamps for Toys Testing Electronic Toy Testing Equipment

Electronic Toy Testing Equipment ISO8124-4,EN71-8

ISO8124-4,EN71-8 Footwear Testing Equipment

Footwear Testing Equipment Fatigue Testing Equipment

Fatigue Testing Equipment Flexing Test Equipment

Flexing Test Equipment Impact Testing Equipment

Impact Testing Equipment Abrasion Testing Equipment

Abrasion Testing Equipment Waterproofness Tester

Waterproofness Tester Friction & Slip Testing

Friction & Slip Testing Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Mattress Testing Machine

Mattress Testing Machine Table Testing Machine

Table Testing Machine Chair Testing Machine

Chair Testing Machine Textile Testing Equipment

Textile Testing Equipment Fabric and Garment Testing Instruments

Fabric and Garment Testing Instruments Color Fastness Testing Equipment

Color Fastness Testing Equipment

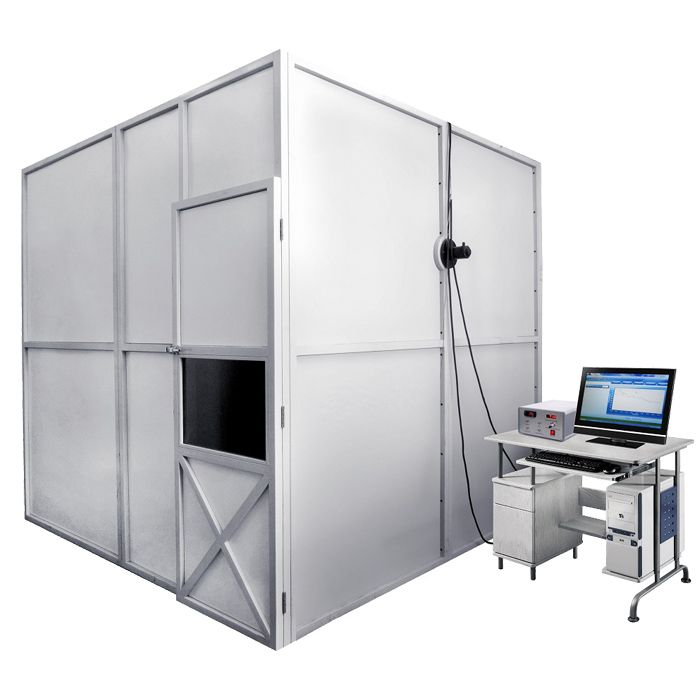

IEC 61034-2 Smoke Density Test Apparatus

Product Description

The 3 Metre Cube Smoke Density Apparatus, in accordance with IEC 61034 or BS 6853, provides a test method for measuring the density of smoke generated from building material or cable burning under a defined fire source.

During the test, when smoke is generated, the optical transmittance is continuously changed by blocking the light path through the smoke, resulting in a minimum transmission value and a test time to reach the minimum transmission

Standards

IEC 61034- 1 & 2: Smoke density test of cable burning under specific conditions

part 1: test device- part 2: test process and requirements

BS 6853: General specification for fire protection in the design and construction of passenger trains

Technical Parameters

|

Frame dimension |

3,000mm(W) × 3,000mm(D) × 3,000mm(H) |

|

Frame material |

Stainless Steel SUS 301 |

|

Transparent sealed window |

100 mm× 100 mm |

|

Foundation Fixed |

Fixture unit |

|

Light Source Power |

DC12V, 100W |

|

Light Source Focus Angle |

48° 4.5° |

|

Light Source Focus Intensity |

1:20 |

|

Photo Cell Diameter |

Ø45 mm |

|

Photo Cell-Cell Type |

Selenium Cell |

|

Exhaust Blower Fan Flow |

7 m3/min ~ 15 m3/min |

|

Exhaust Blower Size |

246(W) x 220(D) x 205(H) mm |

|

Exhaust Blower Material |

Stainless Steel (Inner Fan) |

|

Exhaust Blower Power |

AC220V, 60Hz, φ1, 210W |

|

Exhaust Blower Flow Rate(max) |

8.0m2/min |

| Weight |

500kg |

Features

1.The box body is composed of a cubic shell of 3000mm±30mm. The internal material of the box body is: SUS 304 stainless steel, filled with calcium silicate fireproof material, and the outside is made of iron material and sprayed with plastic;

2.Equipped with wire and cable test rack and hanging weights according to standard requirements.

3.The door of the test box has its own glass observation windows on the opposite sides, with sealed and transparent windows (minimum 100mmx100mm) installed to transmit the light of the horizontal optical measurement system.

4.Photocells and light sources are placed in the center of each window on both walls without physical contact

5.Lamps are configured to provide a certain level of light.

6.Photocells can test the weakening of light caused by smoke

7.Smoke density test photocell and dust-proof protective tube, the output impedance is less than 100Ω.

8.

Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

English

English 中文

中文 Español

Español française

française العربية

العربية Русский

Русский