Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

Toys Testing Equipment

Toys Testing Equipment Physical & Mechanical Testing

Physical & Mechanical Testing Flammability Testing

Flammability Testing Clamps for Toys Testing

Clamps for Toys Testing Electronic Toy Testing Equipment

Electronic Toy Testing Equipment ISO8124-4,EN71-8

ISO8124-4,EN71-8 Footwear Testing Equipment

Footwear Testing Equipment Fatigue Testing Equipment

Fatigue Testing Equipment Flexing Test Equipment

Flexing Test Equipment Impact Testing Equipment

Impact Testing Equipment Abrasion Testing Equipment

Abrasion Testing Equipment Waterproofness Tester

Waterproofness Tester Friction & Slip Testing

Friction & Slip Testing Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Mattress Testing Machine

Mattress Testing Machine Table Testing Machine

Table Testing Machine Chair Testing Machine

Chair Testing Machine Textile Testing Equipment

Textile Testing Equipment Fabric and Garment Testing Instruments

Fabric and Garment Testing Instruments Color Fastness Testing Equipment

Color Fastness Testing Equipment

ISO 11925 Building Materials Flammability Tester

Description

The building materials flammability test furnace is in the normal combustion environment, with a small flame directly impacted the vertical specimen to determine the combustibility of the building products. The flammability test furnace for building materials is based on the principle of Kleinbrenner (Klein Brenner), which is directly impacted by a vertical flame. It is used to determine the combustion performance of B grade building materials (namely, the judgement of burning performance and flame retardant grade B of building materials).

Standards

EN ISO 11925-2

Features

①The operation in line with ergonomic design,test all through the touch screen operation,high degree of automation.Otherwise, the previous test results can be stored and can access the previous test data.

②Controllable automatic lifting of servo motor drive pattern frame.

③The Bunsen Burner can be advanced and retreat and adjusted.

④1.5mm stainless steel plate box

⑤Double angle observation test of 2 heat-resistant tempered glass doors, double (with lock) is convenient and practical.

⑥High pressure automatic ignition and durable combustion.

⑦The point fire source can be automatically tilted by 45 degrees.

⑧The height of the flame is adjusted by the precision regulating valve.

Technical parameters

| Stainless steel plate box | 1.5mm |

| Bunsen burner | can be adjusted forward and backward |

| Diameter of burner | Φ 0.17mm burner with regulator; four ¢4mm air suction inlet |

| Flame length of Bunsen burner | 20mm ± 2mm |

| Ignition source | can be automatically tilted by 45 degrees |

| The Bunsen burner applies a flame time | 15s to the pattern |

| Flame height | Adjusted by precision adjustment valve |

| Sample rack | can move up and down and back and forth |

| Sample holders | 2 pcs |

| Touch screen display | 7 inches Effective display size 15.5cm in length and 8.6cm in width |

| Resolution | 800 * 480 |

| Communication interface | RS232, 3.3V CMOS or TTL, serial port mode |

| Storage capacity | 1G |

| FPGA driver display | "zero" start time, can run after power on |

| Controller | adopts low energy consumption processor, and automatically enters energy saving mode |

| Gas source | >95% propane gas;(user should provide for themselves) |

| Gas pressure | 10kpa~50kpa |

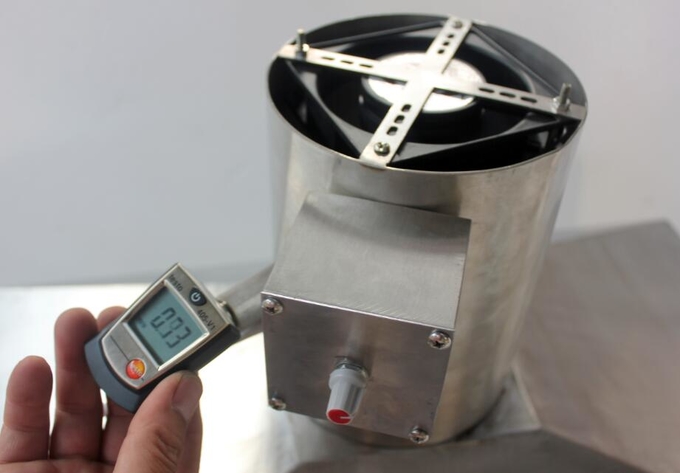

| Flue air velocity | 0.7m/s only on condition of burner burning and draught hood open |

| Time adjustment of continuous flame | 0 ~ 99minutes99seconds |

| Time adjustment of afterflame | 0 ~ 99minutes99seconds |

| Timer accuracy | ≤1s/h |

| Ambient temperature | 15 ℃ ~ 25 ℃; |

| Relative humidity | ≤ 85% |

| Cabinet size | 835 × 400 × 815mm |

| Power supply voltage and power | 220 V, 50 Hz, 100 W |

Flammability Testing Equipment Ignitability Tester...

Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

English

English 中文

中文 Español

Español française

française العربية

العربية Русский

Русский