Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

Toys Testing Equipment

Toys Testing Equipment Physical & Mechanical Testing

Physical & Mechanical Testing Flammability Testing

Flammability Testing Clamps for Toys Testing

Clamps for Toys Testing Electronic Toy Testing Equipment

Electronic Toy Testing Equipment ISO8124-4,EN71-8

ISO8124-4,EN71-8 Footwear Testing Equipment

Footwear Testing Equipment Fatigue Testing Equipment

Fatigue Testing Equipment Flexing Test Equipment

Flexing Test Equipment Impact Testing Equipment

Impact Testing Equipment Abrasion Testing Equipment

Abrasion Testing Equipment Waterproofness Tester

Waterproofness Tester Friction & Slip Testing

Friction & Slip Testing Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Mattress Testing Machine

Mattress Testing Machine Table Testing Machine

Table Testing Machine Chair Testing Machine

Chair Testing Machine Textile Testing Equipment

Textile Testing Equipment Fabric and Garment Testing Instruments

Fabric and Garment Testing Instruments Color Fastness Testing Equipment

Color Fastness Testing Equipment

ISO 9705 Physical Room Fire Corner Fire Test Device

ISO 9705 Flammability Testing Equipment Physical Room Fire Corner Fire Test Device

Product introduction

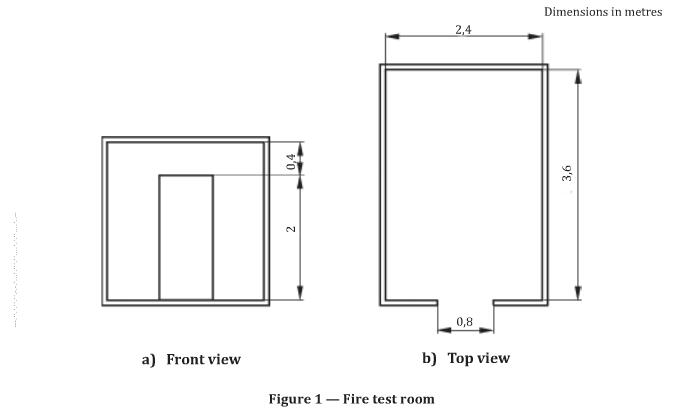

This part of ISO 9075 specifies the test method to evaluate the reaction of wall and ceiling products to fire when installed at the surface of a small room and exposed directly to a specifiled ignition source. The test represents a fire scenario, which starts under well-ventilated conditions in a corner of a specified room with a single open doorway.

Tests performed in accordance with the method specified in this part of ISO 9705 provide data for the early stages of a fire from ignition up to flashover.The method does not evaluate the fire resistance of products.

The method is not intended to evaluate floor coverings. This method is not suitable for sandwich panel building systems, pipe insulation and facades for which specific ISO standards (i.e. ISO 13784, ISO 20632 and ISO 13785,respectively) are available.

Standards

ISO 9705,GA111

Technical Parameters

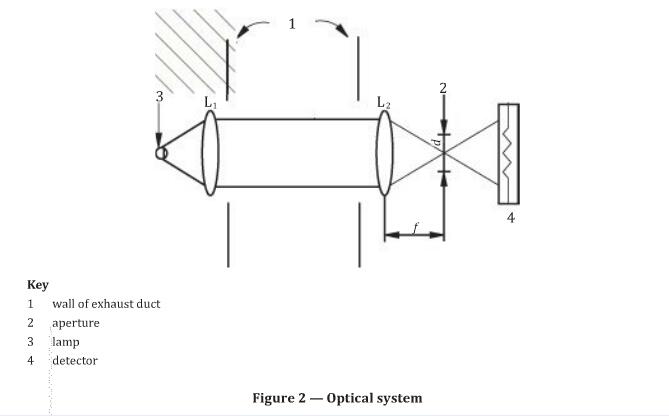

- 19-inch instrument frame containing oxygen, carbon dioxide, and carbon monoxide analyzers

- Oxygen Analyzer is used to measure the oxygen concentration in the gas by measuring the change of paramagnetic pressure. Response Time (T90) 3.5 s, internal signal processing time of 1 s, Pressure sensor (internal) 50~200 kPa, 0 point drift the minimum range on the nameplate 0.5%/ month, measured value drift the current measurement range of 0.5%/month, repeatability error of the current measurement range of 1%, minimum detection limit of the current measurement range of 1%, linear error of the current measurement range of 1%

- Carbon dioxide analyzer and carbon monoxide analyzer are non-discrete infrared type. The principle is based on that the gas molecules have a specific infrared light absorption band and single beam alternating infrared analysis method is used. The minimum detection limit is 1% of the current measurement range, the linear error measurement is within ±1% of full scale, the repeatability is less than ±1% of the minimum range on the nameplate, and the response time (T90 time) is approximately equal to the sample flow rate. Less than 30 seconds at 1.2L/min

- Oxygen Analyzer range for 0-25%, Carbon Dioxide Analyzer range of 0-10%, carbon Monoxide Analyzer range of 0-1%

- Temperature controller is used to control the cold trap. During the test gas extraction process, sufficient moisture is removed

- Gas sampling double-headed pump that can transfer gas samples produced during combustion to analyzers about 30 meters away

- Data Acquisition System (including Operation and Control Programs)

- Acquisition board with 16-bit wide gain range, analog and digital I/O board

- Thermocouple type: K type, range: ambient temperature ~1500 degrees Celsius

- Data acquisition system can be collected through the installation of data logger or field pointer

- The data acquisition system consists of the following parts:

- Bit thermocouple input module, 16-bit analog input module, digital input/output module, 12-bit analog output module, 4 and 8 slot backplane, connector, network module, power supply 24V 5A DC universal power input, data acquisition computer, printer

- The test report must include the following test data: Max HRR (0~2min), Max HRR (0~10min), Max HRR (0~12min), Max HRR (0~20min), Max SPR (0~2min), Max SPR (0~10min), Max SPR (0~12min), Max SPR (0~20min), Average HRR (0~10min), Average HRR (0~12min), Average HRR (0~20min), Average SPR (0 ~10min), Average SPR (0~12min), AverageSPR (0~20min), heat flow-time curve of the geometric center of the floor; mass flow-time curve, total heat release rate-time curve, carbon dioxide CO2 production of the flue gas duct , Carbon monoxide CO production, smoke production, detailed description of fire development status, calibration results, surface temperature-time curve, mass flow-time curve through the doorway, vertical temperature distribution-time curve through the doorway, through the doorway Convective heat-time curve, whether it generates flash light, time to reach flashover

Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

English

English 中文

中文 Español

Español française

française العربية

العربية Русский

Русский