Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

How to evaluate the corrosion resistance of lubricating grease?

How to evaluate the corrosion resistance of lubricating grease? - 2026/1/2

- How to evaluate the corrosion resistance of lubricating grease? A comprehensive guide to lubricating grease corrosion resistance testing and professional testing equipment. A tiny corrosion spot in...

The Hong Kong fire once again rings the alarm: How can laboratories build a safety defense line for building materials through combustion tests?

The Hong Kong fire once again rings the alarm: How can laboratories build a safety defense line for building materials through combustion tests?- 2025/12/25

- The Hong Kong fire once again rings the alarm: How can laboratories build a safety defense line for building materials through combustion tests? The recent serious fire accident in Hong Kong has s...

The Indian furniture inspection market welcomes new regulations!

The Indian furniture inspection market welcomes new regulations!- 2025/11/28

- The Indian furniture inspection market welcomes new regulations! The demand for these testing instruments will soar in 2026. New regulations in India are about to come into effect, and furniture insp...

- More>

How to make your foam & seats sell well

I believe that many friends of car owner, will find the problem of car seat sponge collapse after using for a period of time. It often on both sides of the seat collapse, damage the most serious problem.

For the above situations, we generally use the following methods to solve:

1. A seat cushion is optional. Cushion cushion is undoubtedly the simplest way, but also a very practical method, if the collapse is more serious it is recommended not to use the cushion.

2. Fix the seat. Because most people have no experience in technology, the standard of the seat is not clear, often choose to go to the car shop to repair the seat.

3. Buy the same type of seat. You can buy the same type of seat online or in a store, so you can replace the old seat directly.

4. Replace sponges that have collapsed. Generally, you can change to the garage, which is a very good choice for friends who don't want to change chairs, which is also the most money saving.

As a manufacturer, we should think about this situation: how to avoid such a situation before the problem occurs? How to let the owner in a short time will not encounter such a situation, which can enhance the trust of our customers. For this reason, most manufacturers will test the product after production to ensure product quality.

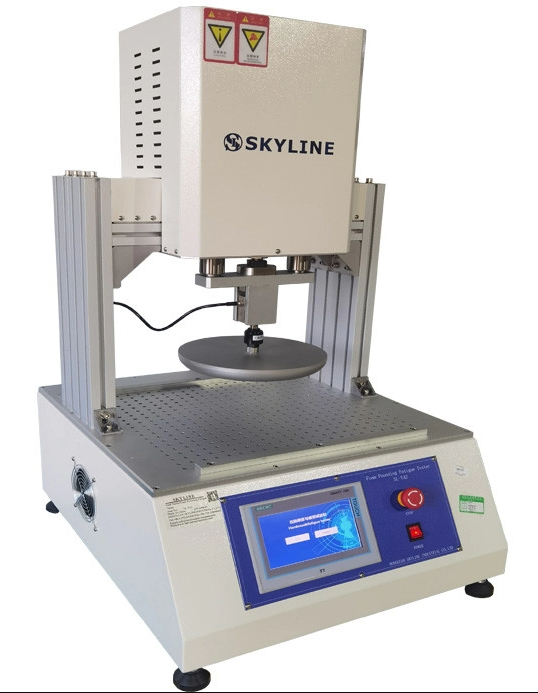

The sponge hardness fatigue tester is used to measure the indentation hardness of porous elastic materials. The polyurethane foam sample can be tested in accordance with the provisions of national standards to accurately measure the collapsion hardness of sponge, foam and other materials, and can also be used to measure the collapsion hardness of the seat foam (such as backrest, seat cushion foam, etc.) that has been produced, and accurately measure the collapsion hardness of the seat foam. In addition, the instrument can also carry out reciprocating compression test for foam polymeric materials, and measure the thickness reduction value and residual deformation rate of the sample, so as to understand the dynamic fatigue characteristics of the material.

High-quality products are one of the embodiment of the core competitiveness of enterprises, according to the standard fatigue performance testing methods for product testing, improve product quality, can ensure that enterprises occupy the market, so as to be able to continue to operate.

- ·New type Crockmeter- Manual Is Newly Released!

- ·Chinese New Year's Holiday!

- ·Skyline Instruments to SASO Installing and Training with a perfect Ending

- ·2014 New Design Toys 2m/s. Dynamic Strength Tester

- ·In 2014, the latest launched Caster and Chair Base Durability Tester

- ·The Blockbuster Launched Chair Stability Tester

Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

English

English 中文

中文 Español

Español française

française العربية

العربية Русский

Русский